Robotic fiber laser welding system is composed of robot motion system and laser welding system. The robot system consists of 6-axises robot and motion control system, which is featured by high repeated positioning accuracy, agile movement, strong tool system, laser indicating and positioning system, motion system, WOBBLE laser welding head, cooling system, etc.

Robotic fiber laser welding system integrates the high degree of freedom and super precision of 6-axises robot with wide range of welding materials,outstanding efficiency and excellent quality of laser welding.

It is processing at a relatively high speed and precision rate during welding, which greatly result in its efficiency of welding, 2-10 times faster than traditional welding.

Moreover, it works at a structural and aesthetic welding seam in consistent width and depth, which save time to grind and polish it afterward. With these conditions above,makes it can be widely used in auto parts, electronic communications, chip manufacturing,metal fabrication, aerospace and other industries.

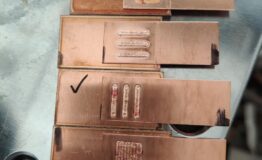

The position system, rotary platform and multi-station welding platform tooling system can be configured as customer’s requirements..

Advantages of laser welding robot

Wobble welding head

Various welding trajectories such as point, line and circle can be realized.

With coaxial blowing device, it can effectively ensure the bright and beautiful welding seam.

Modular design for easy and quick assembly. And the protective lens can be installed in a drawer.

Can be used for up to 2000w laser welding.

Water cooling, multiple seals, longer service life